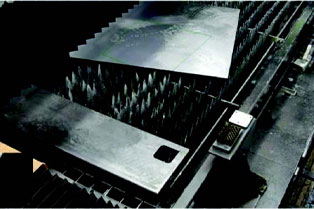

FIBERMAK SIDE LOADING

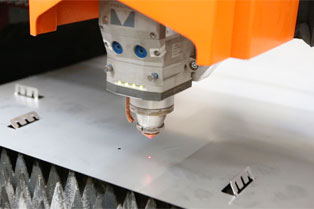

RIGID AND STRONG BODY

Thanks to its strong body with dynamic and static rigidity, it provides a long service life and high precision machining.

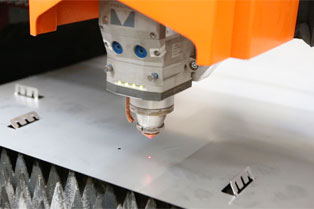

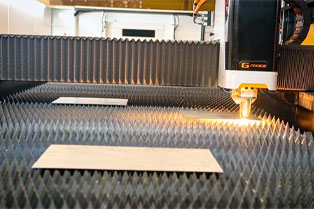

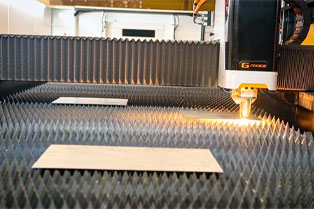

FLY-CUT FEATURE

With Fibermak SL’s fly-cut feature, you can cut both circular and equilateral pieces at great speeds with great quality.

LIFT TRANSITION TYPE

You will get maximum efficiency from your machine by providing transition at maximum speeds with Fibermak SL's lift transition type.

FREQUENCY CUTTING

With fast piercing and the frequency modulation used in sharp corners during cutting, it allows you to cut thick materials in steep corner cuts without melting or without applying radius to the corners.

BACKUP

It is possible to restart the machine within minutes thanks to the option of system backup against possible failures.

MACHINE UPDATE

With the philosophy of continuous improvement, Ermaksan engineers offer the most up-to-date version allowing you to get the most out of your machine.

SUBSCRIBE E-NEWSLETTER

You can subscribe to the e-bulletin to receive information regarding the developments about Ermaksan

ANTI CRASH SYSTEM

ÇARPIŞMA ÖNLEYİCİ SİSTEM

This feature ensures maximum safety while reducing downtime and hardware costs

FILTERING UNIT

EMİŞ ÜNİTESİ

This system, which is activated automatically when the cutting starts, filters the harmful air in the cutting area and gives it back to the

environment. Thus, a healthier working environment is provided.

FREQUENCY CUTTING MODE

FREKANSLI KESİM MODU

With the frequency modulation used in sharp corners, it offers the opportunity to cut thick materials in steep corner cuts without melting and giving radius to the corner.

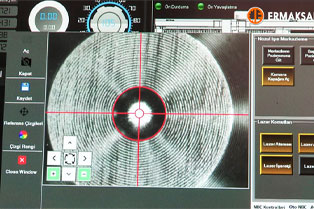

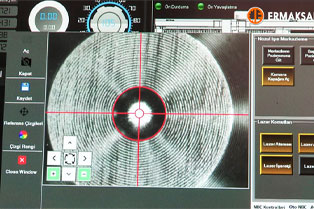

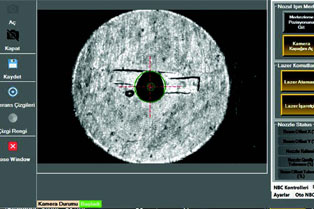

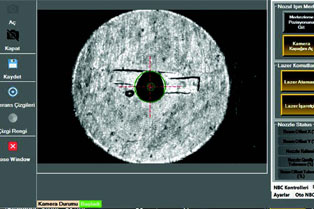

BEAM CENTERING CAMERA

CALBEC-KAMERA DESTEKLİ LAZER IŞIN MERKEZLEME

Laser center adjustment camera is installed into the interior of the machine and this feature is activated by pressing a single button on the operator panel. It can also detect nozzle quality.

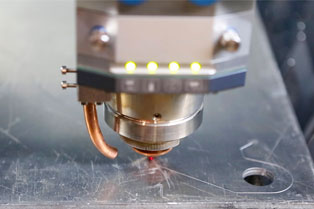

PRECITEC PROCUTTER 2.0 CUTTING HEAD

PRECITEC PROCUTTER 2.0 KESİM KAFASI

With the ProCutter 2.0 cutting head, you will no longer need to choose between high quality and high speed, because you can obtain both.

The cutting head runs smoothly at high laser powers thanks to its advanced cooling concept and extended travel paths.

Fluctuations in the quality of the material to be cut are resolved without any intervention of machine operator.

PROFILE HOLDING TABLE

PROFİL TUTMA TABLASI

With this system, it is ensured that your profiles are realised within the acceptable tolerance range by preventing shifts during the processing process.

PNEUMATIC SHUTTLE TABLE WITH TRANSFER BALLS

PNÖMATİK BİLYALI İKİLİ OTOMATİK MEKİK TABLA (SAC KAYDIRMALI)

DOUBLE AUTOMATIC SHUTTLE TABLE

İKİLİ OTOMATİK MEKİK TABLA

It consists of two movable tables. While processing on the table inside the machine continues, the other table can be loaded with sheet metal or machined parts can be collected. In this way, it allows continuous cutting. In addition to the shuttle table, full automatic loading and unloading systems may also be added.

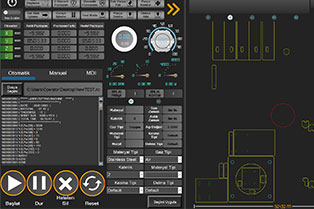

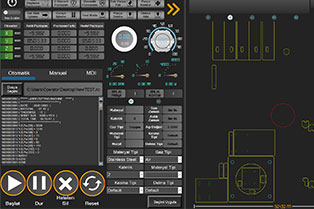

BECKHOFF CONTROLLER

BECKHOFF KONTROLÖR

- With the 21.5'' Beckhoff control panel, Windows10© operating system and multi-touch screen used in Fibermak GEN-5 series laser cutting machines, it can provide all the information and parameters that the operator needs from a single screen and perform the

necessary operations or changes online faster. - All software on the control panel has been written by Ermaksan engineers. Thanks to its flexible structure, the places of the menus used can be changed according to the needs and usage habits of the operator.

- Integrated camera system helps to monitor the cutting proccess on the CNC screen.

- The device works more efficiently by providing information on how often and at what intervals operators should perform device and equipment maintenance.

- Thanks to Industry 4.0 integration, the working efficiency of the machine can be continuously monitored.

- Thanks to the user interface, operators are prevented from accidentally interfering with the system and high-level users can easily control this flow.

- If changes to the cutting parameters are forgotten, the cutting parameters embedded in the system can be recalled.

- It is possible to re-create cutting parameters with precise definitions for different materials and cutting types.

- With the multi-camera system option to be added to the system, online transactions can be monitored and recorded with more than one camera. Information messages can be sent to phone numbers with sim card support option integrated in the operator panel.

- By connecting the system to the internet, machine status and information can be sent to the given e-mail addresses.

- With the adjustable arm added to the control panel, the control panel can be adjusted to the desired angle, inclination and height.

PALLET CONVEYOR

PALETLİ KONVEYÖR

With this system, while the workpieces reach the operator, on the other hand, the slag sticking to the workpieces is prevented by the discharge of the resulting scrap pieces.

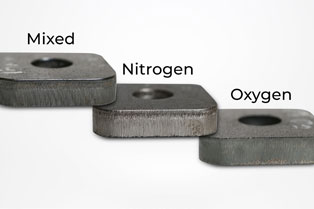

CLEAN - DRY AIR SYSTEM

TEMİZ - KURU HAVA SİSTEMİ

When the necessary infrastructure is created, it can also cut certain materials up to limited thicknesses with high pressure dry air without the need for any other auxiliary gas. Gas costs are saved.

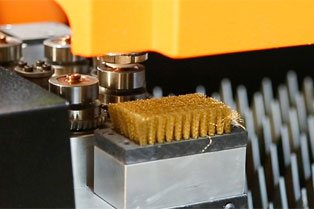

AUTOMATIC NOZZLE CHANGER

OTOMATİK NOZUL DEĞİŞTİRME

According to the selected sheet thickness and type, the system automatically selects and changes the defined nozzle.

INDUSTRY 4.0

ENDÜSTRİ 4.0

Lots of companies around the world are investing to overcome the challenges of the near future, with the most advanced technology for smart manufacturing.

We strongly continue our mission to become the pioneer of the era of smart manufacturing with our strong R & D infrastructure and innovative approach. At Ermaksan, we have many solutions that can help you realize, and accelerate, your Industry 4.0 ambitions. With this approach, developed the ER 4.0 software to make your company a modern smart factory and gain an advantage in the market

Step up to a new manufacturing concept by integrating the smart manufacturing systems and optimizing the manufacturing processes with minimum cost and maximum efficiency. This is a good time for manufacturers to take advantage of Industry 4.0 solutions of Ermaksan, which offers a wide range of opportunities.

As Ermaksan, we are a strategic partner with a comprehensive solution alongside your company to step to the next level.

ERMAKSAN RESONATOR

ERMAKSAN REZONATÖR

Ermaksan's high strength; The fiber laser family offers users single mode and multi-mode options, while also providing excellent power; It also guarantees stability, high efficiency and beam quality.

IPG COOLING UNIT

IPG SOĞUTUCU ÜNİTE

Provides cooling of the relevant parts for continuity and precision in cutting. The laser unit is the collimation part in the cutting head and the part that provides cooling of the lens.

It has a water-based cooling system. It is used with IPG - YLS series resonators.

CENTRAL LUBRICATING SYSTEM

MERKEZİ YAĞLAMA SİSTEMİ

Automatic skid lubrication system extends the life of the machine's skidding system; The oil in the automatic lubrication unit reservoir provides lubrication of the desired area through the grease pump, distributor and hoses in certain periods.

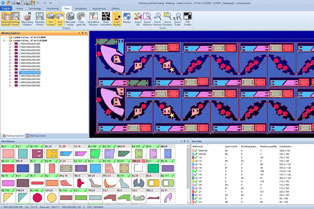

METALIX CAD/CAM SOFTWARE

METALIX CAD/CAM YAZILIMI

• High accuracy Time / Cost analysis

• Nesting with minimum waste rates

• Cameraless terminal license standard

• 2D & 3D import from Solid with Cadlink

• High and effective programming speed

• Mtube in machines with pipe cutting option

• Use of multiple machines with single license

LANTEK EXPERT CUT CAD/CAM SOFTWARE

LANTEK EXPERT CUT CAD/CAM YAZILIMI

This system is a combination of automatic, semi-automatic and manual insertion, providing great flexibility and optimum performance.

T Ø200 PIPE/PROFILE CUTTING

T Ø200 BORU/PROFİL KESME

Your machine is cutting straight sheet metal while your operator saves time by connecting the pipe or profile to be cut on the loading & unloading trolley independent of the shuttle tables.

The pipe or profile fixed between the mirror and the spot is supported by intermediate support apparatus to ensure that the long parts rotate smoothly without deflection, which ensures quality cutting.

Pipe – In addition to the CAD/CAM software provided for flat sheet metal cutting, 3D CAD/CAM software is provided where pictures of pipes and profile parts can be drawn and/or loaded, desired holes and figures can be drilled, nesting and cutting simulation can be performed in addition to our machines supplied with profile cutting option.

AUTOMATIC PROFILE ALIGNMENT

OTOMATİK PROFİL HİZALAMA

This feature prevents measurement drifts that may occur in profile cuts.

SHEET SORTING

SAC AYIRMA

If there is an obstacle to cutting at the point selected by the image processing method, the cutting offset is made by detecting it on the image.

AUTOMATIC BEAM CENTERING AND NOZZLE QUALITY DETERMINATION

OTOMATİK IŞIN MERKEZİ BULMA VE NOZUL KALİTE TESPİTİ

Thus, the center adjustment is made thanks to the declared commands. During center setting, the nozzle loses its circular shape. If this situation exceeds the tolerance that will affect the cutting, a warning will appear and a nozzle change request is made.

AUTO SHEET / AUTO MULTISHEET

OTOMATİK / ÇOKLU SAC BULMA

By assigning the jobs added to the work list to the sheet metals detected via the camera, it allows defining which part will be cut on which sheet. (Auto MultiSheet)

Maxphotonics PRO Series

Maxphotonics PRO Serisi

Maxphotonics PRO-Series stands as the flagship of the Max family's CW lasers, integrating the most advanced technology and laser cutting expertise. Designed for the most demanding markets, the PRO-Series delivers top-notch performance where excellence is essential.

PRODUCT FEATURES

- Top-notch quality and performance

- Multiple control interfaces for easy integration

- Performance Level D (PL-d) safety standard

- ZERO power degradation for up to 3 years to safeguard your investment and productivity

- Complies with major EU/US standards/certificates, including CE, ETL, FDA; UL compatible

Maxphotonics ELITE Series

Maxphotonics ELITE Serisi

Maxphotonics ELITE-Series is a laser source that balances cost and performance effectively. It incorporates widely used and well-qualified optical components to achieve good cost-effective performance without sacrificing reliability.

PRODUCT FEATURES

- Multi-functional I/O Interface

- Full Coverage Certificates, Including CE/FDA/ETL(UL)

- Excellent Cost and Performance Compound

- Performance Level D(PL-d)

- Plug and Play

- Effective Power Redundancy